Controls from RBS

Coordinated control modules for more application flexibility

With complex machines and systems, the question always arises as to how they should be controlled. In principle, this always depends on the tasks to be completed. The trend in control technology is towards modular, software-based function modules. Preference is given to application-specific controls that are similar to those programmed, but nevertheless offer different functional ranges.

RBS control systems monitor and control all decisive processes of the individually designed intralogistics solutions. Occupational safety and operational reliability are also important factors here. Control modules developed by RBS, proven in practice, ensure the economic efficiency of a plant with high flexibility of use. These modules include the PLC level, paperless picking using the pick-by-light method, visualization and standardized interfaces for connection to a warehouse management system.

A tailor-made system control offers many advantages: Production safety, economy, reliability and future orientation. Electrical interfaces and transfer points within the conveyor technology as well as the protocols to be used are defined in advance. The responsibilities for the individual sub-areas are likewise defined. In addition to planning and coordination, RBS also handles PLC programming, installation and start-up on site.

Pick by Light

RBS paperless order picking and commissioning

- optimizes processes,

- reduces errors,

- increases performance

Pick by Light, the paperless picking system from RBS supports you in optimizing your processes and reducing the error rate at the same time.

In addition, a higher picking performance is achieved due to the route-optimized guidance. This is a considerable competitive advantage, especially with regard to Internet trading with its short delivery times.

PLC

RBS controls adapted to your individual requirements regarding performance and complexity.

Each RBS conveyor system meets your individual requirements regarding performance and complexity of the application.

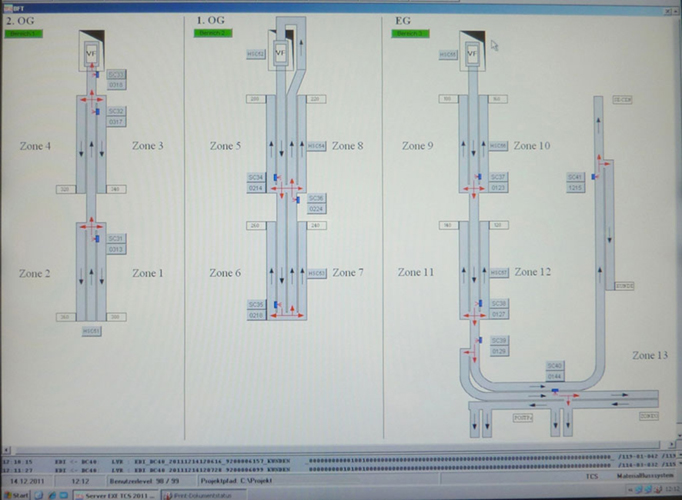

Visualization

RBS visualizations - all processes well in view and accessible.

So that your PLC is not a black box, but you have all processes in view and access.

In order to monitor, trace or even intervene in the control processes without special programming knowledge, RBS equips all plants with an individual process visualization on request.