50 Years RBS - Internal material flow from a single source

50 Years RBS - Internal material flow from a single source Controls

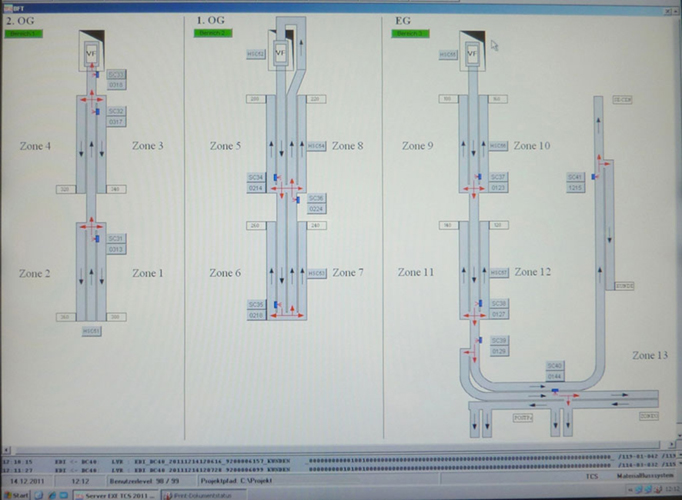

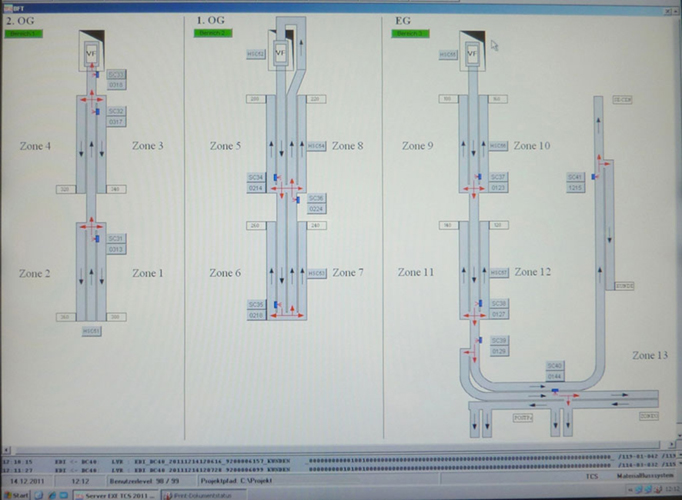

RBS Visualization

All processes at a glance

The visualization of processes and equipment facilitates the understanding of processes as well as monitoring and ensures the comfortable equipment operation. In most cases, it also includes an immediate logging of the process data for diagnosis. This helps to understand and analyse complex processes.

So that your PLC is not a black box, but you have all processes in view and access.

The need for a visualization that is quick to grasp and easy to understand with a suitable Human Machine Interface (HMI) increases with the complexity of the processes and procedures to be monitored.

On request, RBS provides an individual visualization in almost unlimited size and complexity for the equipment designed for its customers. This enables the operation and monitoring of the systems without any special programming knowledge.

Feedback on certain function sequences or fault messages are displayed graphically and in text form. This also allows regulatory interventions in the specified control sequence.

The interaction of a well thought-out, clear visualization with a reliable PLC is optimal for a large part of the control tasks. Established technical and programming standards ensure that the components are up-to-date and that long-term product maintenance is carried out.

RBS Programmable Logic Controler

Adapted and optimized for individual control tasks

By using a programmable logic controller (PLC), all types of control functions and also control functions can be executed. A compact design, simple programming and high flexibility are good reasons for using programmable logic controllers (PLCs) in intralogistics systems. In addition, they offer the possibility of remote maintenance, various networking options with other IT systems and, last but not least, very high reliability.

RBS offers you the right controllers for the most diverse automation requirements.

RBS prepares a function plan for the control system and the process visualization of the plant to be designed based on the specifications, which describe e.g. the functional requirements of the control system.

Even after successful acceptance, the RBS technicians are still available for service tasks such as remote diagnosis or remote maintenance. In addition, an individual on-call service is offered.

Controls from RBS

Coordinated control modules for more application flexibility

With complex machines and systems, the question always arises as to how they should be controlled. In principle, this always depends on the tasks to be completed. The trend in control technology is towards modular, software-based function modules. Preference is given to application-specific controls that are similar to those programmed, but nevertheless offer different functional ranges.

RBS control systems monitor and control all decisive processes of the individually designed intralogistics solutions. Occupational safety and operational reliability are also important factors here. Control modules developed by RBS, proven in practice, ensure the economic efficiency of a plant with high flexibility of use. These modules include the PLC level, paperless picking using the pick-by-light method, visualization and standardized interfaces for connection to a warehouse management system.

A tailor-made system control offers many advantages: Production safety, economy, reliability and future orientation. Electrical interfaces and transfer points within the conveyor technology as well as the protocols to be used are defined in advance. The responsibilities for the individual sub-areas are likewise defined. In addition to planning and coordination, RBS also handles PLC programming, installation and start-up on site.

Pick by Light

RBS paperless order picking and commissioning

- optimizes processes,

- reduces errors,

- increases performance

Pick by Light, the paperless picking system from RBS supports you in optimizing your processes and reducing the error rate at the same time.

In addition, a higher picking performance is achieved due to the route-optimized guidance. This is a considerable competitive advantage, especially with regard to Internet trading with its short delivery times.

PLC

RBS controls adapted to your individual requirements regarding performance and complexity.

Each RBS conveyor system meets your individual requirements regarding performance and complexity of the application.

Visualization

RBS visualizations - all processes well in view and accessible.

So that your PLC is not a black box, but you have all processes in view and access.

In order to monitor, trace or even intervene in the control processes without special programming knowledge, RBS equips all plants with an individual process visualization on request.

RBS Pic-by-Light

Order picking as error-free and fast as possible

The picking and sorting of goods, components or items for customer or production orders plays an important role in internal logistics. Errors made here delay all subsequent production or delivery processes. The additional costs incurred, for example, due to incorrect shipping, a costly follow-up check and missing or incorrect parts within the production process are not insignificant.

RBS offers you the right controllers for the most diverse automation requirements.

RBS supports its customers with pick-by-light systems to optimize internal material flow processes, increase throughput and reduce error rates. This represents a considerable competitive advantage, especially with regard to Internet trading with its short delivery times.

„Pick-by-Light“ is one of the most widely used paperless picking systems. This system has a signal lamp, a display, an acknowledgement button and, if necessary, an input or correction button on each storage compartment.

If the order picking container is ready at the picking position, the signal lamp lights up at the storage compartment where goods have to be picked and the number of goods to be picked is shown on the display.

The order picker then only has to confirm the withdrawal by pressing a button. This means that the change in stock is also simultaneously reported to the warehouse system in real time.

The elimination of paper lists, reduced search times and the associated increase in picking performance, the reduction of picking errors and ultimately the increased flexibility for changing order positions are just a few of the major advantages that order picking via light signals offers over manual order picking techniques.

The elimination of paper lists, reduced search times and the associated increase in picking performance, the reduction of picking errors and ultimately the increased flexibility for changing order positions are just a few of the major advantages that order picking via light signals offers over manual order picking techniques.

The direct connection or feedback to a warehouse management system also provides an additional benefit for inventory support and replenishment control.

RBS selects the optimum solution for each storage location from a large selection of user-optimised displays. As a modular component of the RBS control system, the pick-by-light system is also connected to the ERP program or a warehouse management system via predefined interfaces.